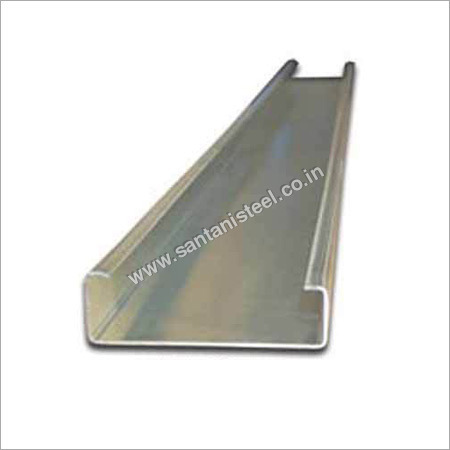

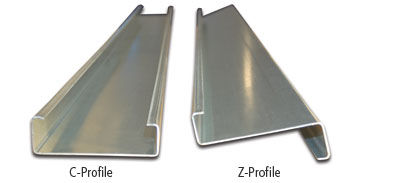

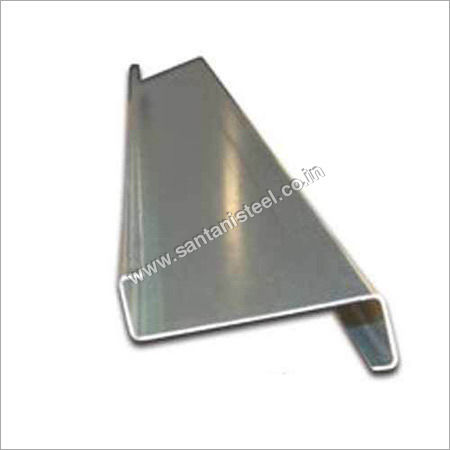

C Purlin

75 INR/Kilograms

Product Details:

- Features Weatherproof, Lightweight

- Load Capacity High Load Bearing

- Purity Industrial Grade

- Material Grade SS316 / SS304 / As specified

- Application Construction

- Machines Type Roll Forming Machine

- Installation Type Pre-punched for Easy Installation

- Click to View more

X

C Purlin Price And Quantity

- 1 Kilograms

- 75 INR/Kilograms

C Purlin Product Specifications

- Silver

- 1.5 mm - 3 mm

- Cold Rolled Channel

- Construction

- 2-100 mm

- Stainless Steel Alloy

- Roll Forming Machine

- Pre-punched for Easy Installation

- Galvanized

- SS316 / SS304 / As specified

- Construction

- Corrosion Resistant, High Strength

- C Purlin

- Variable as per section and length

- Industrial Grade

- C Shape

- Weatherproof, Lightweight

- High Load Bearing

Product Description

With rich experience and in-depth knowledge, we are engaged in offering a superb range of C Purlin. These purlins can be used over single spans, unlapped and lapped continuous spans in multi-bay buildings for supporting the roof structures. We employ advance machines and quality approved materials to manufacture C Purlin, in accordance with industry set norms and standards. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality.

Features:

- Robust construction

- Corrosion resistance

- Smoothly finished

Specifications:

- Size: 2 mm to 100 mm (heavier on request)

- Length available: As customer specific length

- Stainless Steel: A182/A479-TP304/L/H, 316/L/H, 316Ti, 317/L, 321/H, 904L

- Nickel Alloys: 200, 400, K500, 600, 625, 800, 825

- High Alloys: alloy 20, alloy c, alloy c276, alloy b2

- Duplex Steel: UNS31803, UNS32205, UNS S32750 & S32304

Product details

| Size | 2-100 mm |

| Usage/Application | Construction |

| Position | Exterior |

| Shape | C Type |

| Surface Treatment | Galvanised |

| Material | Stainless Steel Alloy |

| Standard | ASTM 182 |

Versatile Construction Support

C Purlins are widely used in construction for roofing, wall support, and structural framing. Their high load-bearing capacity and corrosion-resistant properties make them an essential choice for modern building projects. With variable sizes and thicknesses, our purlins can be tailored to suit diverse architectural requirements, providing both strength and longevity.

Premium Material and Surface Protection

Manufactured from SS316 or SS304 stainless steel alloy, our purlins are galvanized for superior protection against rust and environmental damage. The zinc coating, coupled with cold-rolled processing, not only extends the purlins lifespan but also maintains aesthetic integrity. These features ensure that both indoor and outdoor applications benefit from lasting durability.

Easy Installation and Low Maintenance

Each C Purlin is pre-punched, allowing for quick and accurate installation on-site. Thanks to the smooth edges and lightweight design, handling and fixing the purlins require minimal labor. Maintenance demands are low due to the high-grade materials and weatherproofing treatments, saving time and long-term costs for builders and end-users.

FAQs of C Purlin:

Q: How are the C Purlins installed on construction sites?

A: C Purlins are supplied with pre-punched holes and smooth edges, simplifying the installation process. They can be quickly fixed to primary structures using standard fasteners, reducing on-site labor and installation time.Q: What benefits does the zinc-coated, galvanized surface provide?

A: The galvanized zinc coating offers robust corrosion and weather resistance, which extends the lifespan of the purlins and protects them against harsh environmental conditions. This makes the product ideal for both indoor and outdoor structural applications.Q: When should C Purlins be considered over other structural supports?

A: C Purlins are especially suitable when a combination of high load-bearing capacity, lightweight construction, and resistance to corrosion is required. They are preferred in roofing, wall frameworks, and industrial building projects.Q: Where can C Purlins be used in construction?

A: They are predominantly used in roofing frameworks, wall cladding supports, and as secondary structures in factories, warehouses, and commercial buildings. Their versatility and strength allow application in a wide range of construction scenarios.Q: What is the typical manufacturing process for these C Purlins?

A: Our C Purlins are produced using a roll-forming machine, shaping high-quality stainless steel alloys through a cold-rolling process. This ensures precise dimensions, smooth edges, and consistent quality throughout each section.Q: How does the choice of material grade like SS316 or SS304 benefit my project?

A: Using SS316 or SS304 stainless steel alloys increases the purlins resistance to corrosion, chemical exposure, and high humidity environments, thus ensuring structural stability and long service life in demanding conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Stainless Steel Purlin' category

We can meet Bulk Quantity requirements of clients based across Vadodara, Gujarat, Rajasthan, Maharashtra and Madhya Pradesh.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free